In a nutshell:

- Predictive maintenance with generative AI can help businesses minimize equipment downtime, optimize maintenance schedules, and reduce costs.

- Implementing predictive maintenance strategies can be challenging due to data availability, lack of data science expertise, and changing workflows.

- Generative AI addresses these challenges by automating data analysis, creating synthetic data sets, and simplifying workflow changes.

- Generative AI learns from existing data sets and generates new and original insights, making it a powerful tool for enhancing predictive maintenance strategies.

- The combination of predictive maintenance and generative AI can revolutionize how businesses approach equipment maintenance, leading to increased productivity, reduced breakdowns, and lower maintenance costs.

"For want of a nail the shoe was lost; for want of a shoe the horse was lost; and for want of a horse the rider was lost." Clearly, this stable needs to catch up with developments in predictive maintenance with generative AI.

So often, early signs of equipment failure or malfunctions are missed. Humans can try their best to keep up with every little detail, but as equipment becomes more complex and the quantity of maintenance data ever larger, that's a challenging task. At the same time, keeping your business's equipment and critical assets in top-functioning order is vital to customer satisfaction and efficient operations. To achieve these goals, predictive maintenance solutions have boomed: The global predictive maintenance market is expected to reach $12.3 billion by 2025. Fortunately, generative artificial intelligence (aka GenAI) offers an effective way to resolve these issues.

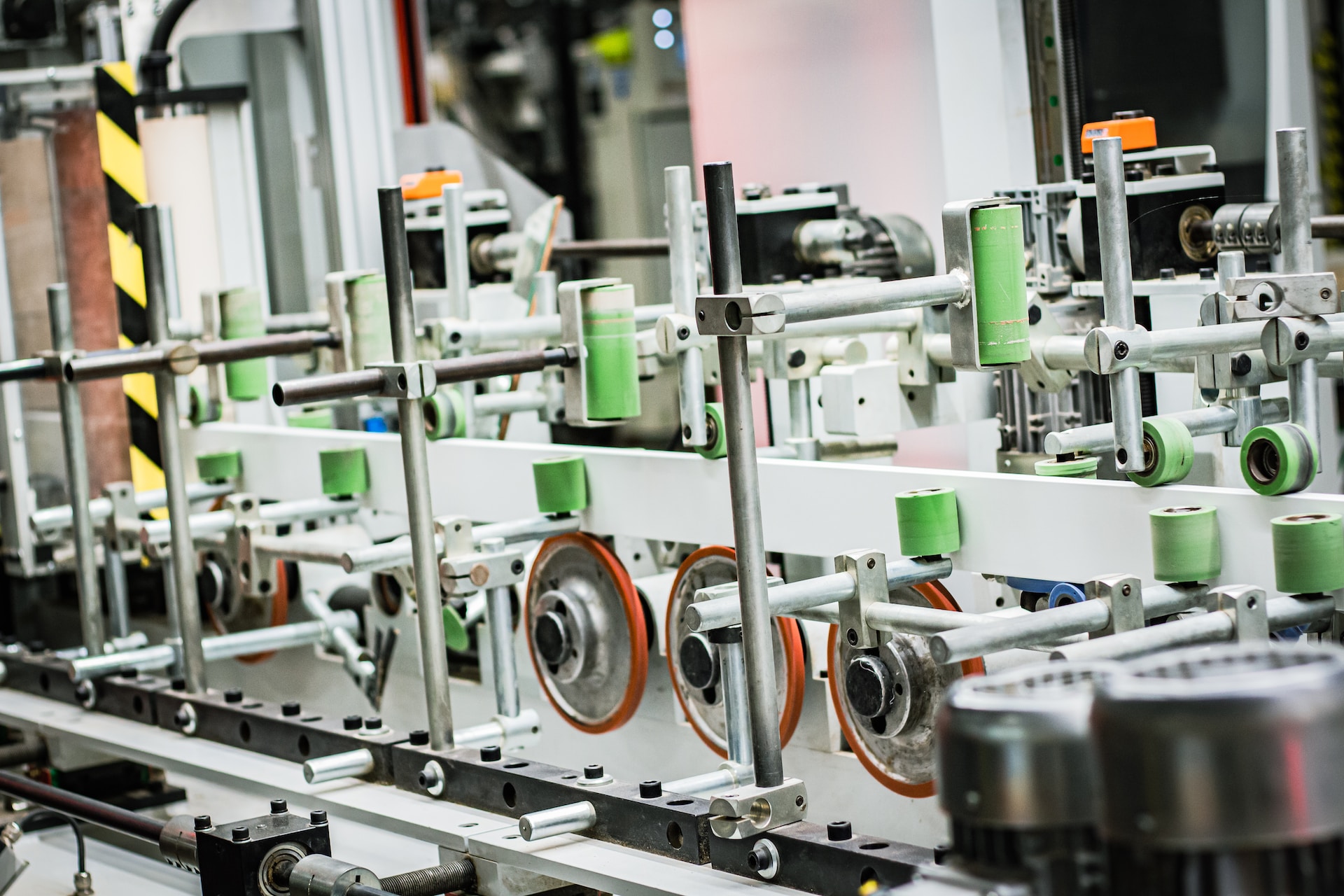

Photo by Harman Pannu on Unsplash

Proactively identifying potential faults and failures can help businesses minimize equipment downtime, optimize maintenance schedules, and save on spending. By analyzing historical data and historical sensor data, companies can make accurate predictions about potential breakdowns and minimize machine downtime. A machine learning model can optimize maintenance schedules and reduce maintenance costs. This is especially true for industries that rely on equipment, like manufacturing and vehicle rental fleets.

However, the demands on data availability, data science expertise, and changing workflows make implementing effective predictive maintenance strategies challenging.

Generative AI, a subset of artificial intelligence that focuses on creating new and original content, provides a promising solution to the challenges faced in predictive maintenance.

Let’s explore the intersection of predictive maintenance and generative AI and how this combination can revolutionize how businesses approach equipment maintenance.

"On average, predictive maintenance increases productivity by 25%, reduces breakdowns by 70% and lowers maintenance costs by 25%."

— Deloitte Analytics Institute research

The Challenges of Implementing Predictive Maintenance

Predictive maintenance offers tremendous benefits but has unique complexities and challenges that must be addressed. Understanding these hurdles is vital to using predictive maintenance wisely and paving the way for its streamlined integration in your business operations.

The biggest challenge of implementing predictive maintenance lies in its inherent complexity. Risk management is a key aspect of implementing predictive maintenance. By leveraging machine learning models and analyzing historical data, businesses can identify potential failure events and take proactive measures to prevent them. This not only reduces machine downtime but also minimizes maintenance costs.

However, unlike traditional maintenance strategies, predictive maintenance requires constantly monitoring machinery and equipment for signs of potential failure. This involves collecting and processing large volumes of data, which can be daunting for businesses not equipped with the necessary resources or technical expertise.

Similarly, the lack of a highly skilled data science team can hamper the implementation of predictive maintenance. However, with the help of generative AI, businesses can overcome this hurdle. With tools like Pecan's Predictive GenAI, which adds a layer of natural language conversation over advanced machine learning technologies, data analysts and businesspeople can automate the data analysis process. This integration of GenAI tools eliminates the need for a team of data scientists and makes predictive maintenance more accessible to businesses of all sizes.

Photo by Eric Prouzet on Unsplash

Successful implementation of predictive maintenance requires a considerable amount of high-quality data. To accurately predict equipment malfunctions, businesses need substantial high-quality data. However, many companies lack the necessary data engineering resources to handle complex data sets. Generative AI can address this challenge by creating new synthetic data sets for analysis, expanding the potential training data for predictive models. This approach bypasses the need for extensive pre-existing data and reduces the number of employees required for the job.

This data is then analyzed and processed to generate actionable insights that help to predict equipment malfunctions. With generative AI, these predictions can be made much more actionable. Instead of digging through data to find key insights, generative AI can translate predictions into specific recommendations and action plans for maintenance tasks.

Predictive maintenance also brings about changes in traditional workflows and routines. Implementing predictive maintenance requires shifting from reactive to proactive maintenance strategies. This shift often requires training for staff unfamiliar with this new method of business, which makes implementing this type of technology more complex. Generative AI can simplify this process by automating and optimizing many of the workflow changes, easing staff transition and reducing resistance to change.

While substantial and difficult to manage, these challenges can be effectively addressed with the right technology, training, and skilled staff members. The solution lies in applying generative AI, a powerful tool that can ease the implementation process, streamline workflows, and accurately predict equipment malfunctions.

Photo by Hannah Brown on Unsplash

Understanding Generative AI

AI technology has evolved significantly from simple rule-based systems to more complex neural networks and deep learning. AI can be categorized broadly into two types: predictive and generative AI. Generative AI is a cutting-edge technology that surpasses traditional rule-based systems and complements predictive AI.

Predictive AI learns from its input data to classify or predict an outcome. It is important to note that predictive AI does not generate something new or original. Generative AI, on the other hand, goes one step further. Although equipped with the same ability to learn from input data, generative AI generates new, original content. By learning from existing data sets, generative AI can create new and original content, such as text, images, or synthetic data. This unique capability sets it apart from predictive AI and makes it a powerful tool for enhancing predictive maintenance strategies.

One example of generative AI is the generative adversarial network (GAN), which uses two models to create and evaluate new data instances. This game-like approach allows generative AI to produce credible, original data that mimics real-world intricacies.

How Generative AI Works

Generative AI works by learning from existing data sets and then creating new data that resembles the original data set. This iterative process allows the AI system to refine and develop its knowledge base continually.

Generative AI can create accurate models for forecasting equipment malfunctions by generating new scenarios and anticipating potential outcomes. This is achieved through predictive AI in the form of machine learning algorithms that can identify patterns and trends in the data. These models leverage their learned experiences to construct new insights. They do this once they’re trained on the initial set of data.

The training process is the stage where the AI learns the rules obtained from patterns and correlations in the data it's being fed. Once the model has been adequately trained, it can generate new data. It uses the learned rules to create new scenarios or predict potential outcomes.

This constant learning and optimization cycle allows generative AI to continuously enhance its capabilities, providing businesses with increasingly accurate insights. As it generates new data, this data can be evaluated and used to refine the model further and produce better results. The newly acquired knowledge is looped back into the system, creating a constant learning and optimization cycle.

Essentially, generative AI’s superpowers are its ability to learn from existing data and its capacity to generate new and original insights. This capability makes it a game changer in predictive maintenance because it can create accurate models to help anticipate potential equipment malfunctions and other potential issues.

Photo by Evaldas Grižas on Unsplash

The Intersection of Predictive Maintenance and Generative AI

The combination of predictive maintenance and generative AI can be a game-changer for businesses. Using generative AI can address some of the biggest challenges faced by predictive maintenance strategies. The biggest problems revolve around data availability, the need for skilled data scientists, and changing workflows.

To ease the way, Pecan uses generative AI to help users develop predictive models that support predictive maintenance intiiatives. With the use of this platform, implementing predictive maintenance strategies can be much easier. Rather than requiring a large team of data scientists to analyze data and generate predictive models, generative AI can handle things more efficiently, accurately, and often with a higher level of detail. With natural language interfaces that accept user text input, Pecan makes receiving individualized predictions for specific predictive maintenance needs more accessible than ever.

Generative AI in predictive maintenance is rapidly becoming vital in several sectors, including manufacturing, fleet management, and industrial production. These sectors require complex equipment and machinery to function. Businesses can create models specifically suited to their industry sector and critical assets by applying generative AI to predictive maintenance.

"Among those establishments that primarily rely on preventive and predictive maintenance, predictive maintenance was associated with 15 % less downtime, 87 % lower defect rate, and 66 % less inventory increases due to maintenance issues."

— NIST, "Research Suggests Significant Benefits to Investing in Advanced Machinery Maintenance"

For example, in vehicle fleet management, generative AI can predict and model the maintenance requirements for different types of vehicles, considering each vehicle’s usage and age. Pecan's Predictive Chat can help users identify exactly what they want to predict regarding vehicles, what timeframe is relevant, and which data will assist in obtaining accurate predictions.

This highly tailored predictive maintenance strategy enables maintenance teams to effectively manage the broad variety of equipment present in their operations. The result is better upkeep, extended equipment life, and avoiding unexpected breakdowns.

Photo by Ansel Huang on Unsplash

Additional Benefits of Generative AI in Predictive Maintenance

Reducing Human Error with GenAI

While humans do their best to keep up with today's massive datasets, they're simply not a match for AI. Generative AI, with its capacity to simulate and understand complex patterns, can analyze historical data to discern patterns associated with human-induced errors in machinery or systems. Organizations can proactively identify weak points or potential failure modes affected by human actions. With this proactive identification, they can intervene in advance to prevent operational disruptions. This benefit enhances the reliability of predictive maintenance systems. It contributes to a more resilient and error-resistant operational environment, minimizing downtime and optimizing overall system performance.

Weather and Predictive Maintenance with GenAI

Predicting the weather may be tough, but generative AI is capable of forecasting maintenance requirements based on nuanced weather conditions using the best information we have. GenAI delves into data patterns to identify relationships between equipment well-being and dynamic weather phenomena. This analysis provides the foresight needed to proactively address potential wear and tear caused by weather.

Employee Schedule Optimization with Predictive Maintenance

Predictive maintenance with GenAI enhances maintenance scheduling by optimizing it in alignment with both employee availability and workload considerations. GenAI tools can systematically analyze data related to employee schedules, considering factors like availability and existing workloads. By discerning patterns and correlations within this data, the technology empowers organizations to fine-tune maintenance schedules. The result balances skilled personnel's availability and current work commitments. Here again, predictive maintenance supports efficiency and streamline operations.

"Poorly managed maintenance schedules can [account] for as much as 40% of the operational budget."

— Process Worldwide

Customer Demand and Predictive Maintenance

Taking 25% of your rental fleet out of commission during the summer travel season? Doing maintenance on e-commerce website servers during consumers' holiday shopping sprees? Generative AI offers a way to predict maintenance needs based on customer demand. This means businesses can use this innovative technology to foresee when maintenance might be needed, then plan to carry out those tasks when customer activity is low. This strategic approach minimizes disruptions, ensuring that crucial preventative maintenance tasks are addressed without inconveniencing customers during peak activity periods.

The Future of Predictive Maintenance With Generative AI

The future of predictive maintenance with generative AI is incredibly promising. This technology enables the creation of more accurate and detailed predictive models refined to fit businesses' unique needs, enhancing equipment maintenance routines.

By adopting generative AI early, businesses can gain a competitive advantage by optimizing preventive maintenance schedules, reducing costs, and maximizing productivity. This technology allows for creating more accurate and detailed predictive models that will ultimately enhance equipment maintenance routines.

Generative AI in predictive maintenance is more than just a technological innovation. By incorporating generative AI into predictive maintenance strategies, businesses can overcome challenges and implement effective predictive maintenance workflows.

Now is the opportune moment to harness the power of generative AI for predictive maintenance. Pecan's advanced predictive analytics platform incorporates Predictive GenAI, our fusion of predictive and generative AI technologies that makes implementing predictive maintenance far easier and faster, without requiring data science resources.

By understanding generative AI, its application in predictive maintenance, and the future implications of this technology, businesses can gain a competitive advantage among their peers. Get in touch now or start a free trial today to get started.